…I could watch people do it all day.

Our last week in Kasese started, as usual, with car trouble.

Last week had been the break-in and getting the lock repaired so that we could shut the door. This week it was ‘Death Wobble’.

It sounds bad. It feels just as bad. Anything over 50kph, when turning the steering wheel even slightly left and the whole front of the car goes into a tank-slapper. The steering wheel jumped out of my grip as if the wheels were square and the front of the car started dancing across the road, out of control until the speed dropped below 30kph.

On these roads (potholed, rutted, littered with axel-crushing speed humps and flooded with lunatic drivers) it’s like playing Chicken with every vehicle coming the other way.

Death wobble can be caused by a number of problems (stabiliser bushes, track-rods, swivel-ball joints, etc). None of them something I wanted to tackle myself.

We found a local mechanic and he had his team set to work.

In the meantime, we had work to do down at the new AWU library. The UK team had thankfully allowed us to relocate the street-boys Fuel Briquette project within the library yard (better security, better working environment, good for community involvement, etc) and that meant we needed to get some additional shelter and storage facilities built quickly.

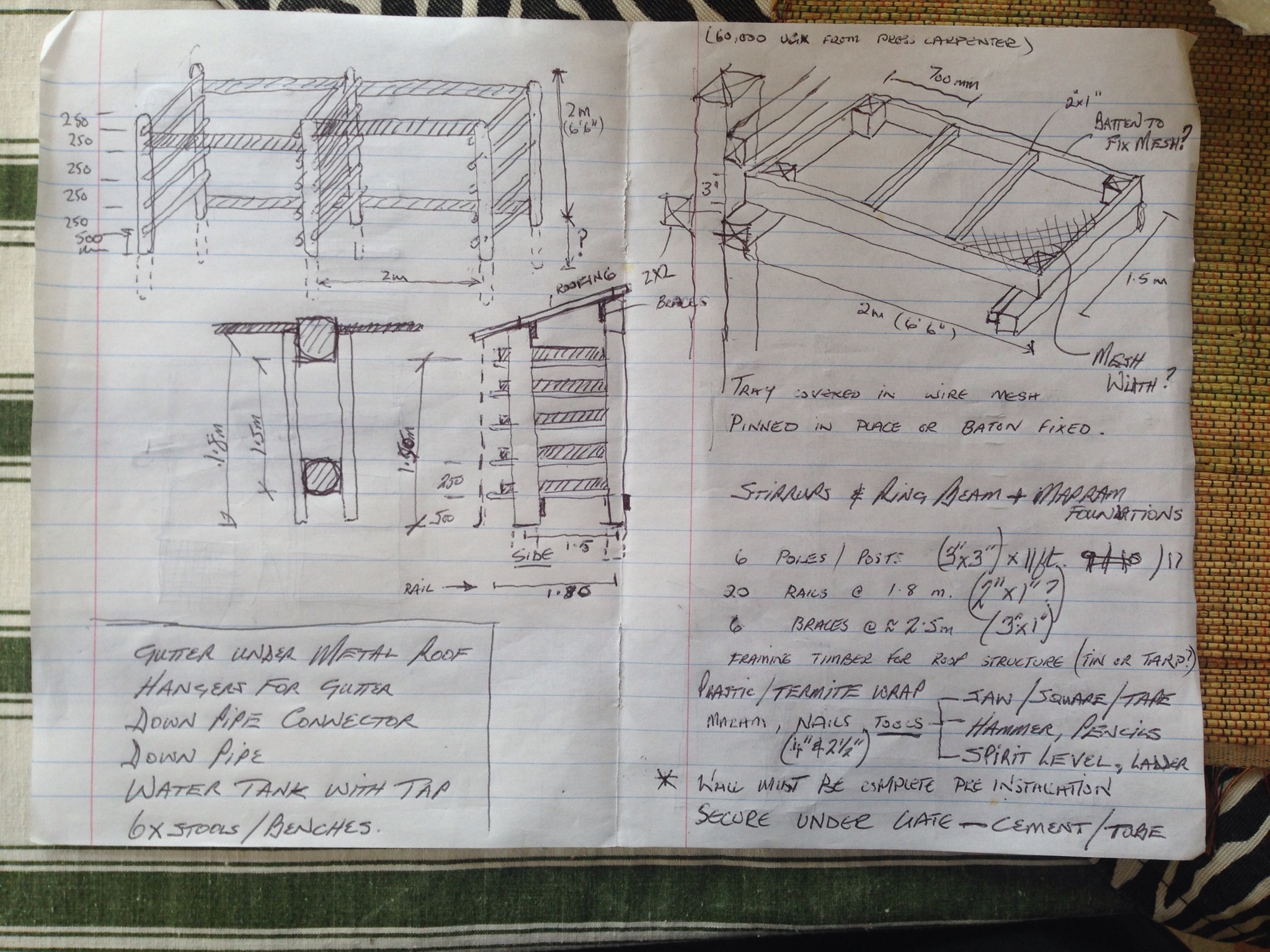

We needed drying racks for the briquettes as they come out of the press and shelter for the boys to work (from the sun 70% of the day and torrential rain the other 30%).

The team are expected to make around 1,500 Fuel Briquettes a week and they need to dry for around 5 days before they can be sold. Space is at a premium in the library grounds so heavy-duty stacking would be needed.

The AWU NGO team had generously approved a budget to get the project off the ground and we didn’t want to waste it hiring contractors to build what we needed. Jethro (one of the evangelists in the team) and I decided we could do it ourselves – actually I think I bullied Jethro into it, but he proved to be an absolute star

Highly detailed material schedules, programmes and Technical Design Drawings were commissioned from our specialist design team.

And we set to work.

Half the battle here is getting the materials. There’s no B&Q or Home Depot. All wood here comes as 11ft long, rough 6-inch wide planks or logs, straight from the forest.

Actually, ‘straight’ is the last thing they are.

If you want any other sizes you collect the 11ft (3.5m) planks, have half a dozen of them transported on the back of a bicycle (yes, bicycle) to a carpenter and he cuts them into 2×2, 2×4, 2×1 etc.

Hammers, nails, saws, squares, roofing materials, etc involve another treasure hunt. The nearest thing we could find to a spirit-level was an App on my iPhone.

The perimeter wall had been raised a couple of feet for additional security and, by the end of the first day, we’d had most of the materials delivered. The first of the frames was measured, cut and assembled before we were rained off.

Day 2 was all about attaching the 2nd frame (so that we’d have 10 drying racks in total) and sinking the whole thing into footings so that it wouldn’t topple.

Hot, sweaty, heavy manual labour. After 30 years behind a desk it came as a bit of a shock to the system.

Mind you, I did spend a fair amount of time with my eyes closed. In a previous existence (seemingly a lifetime ago) construction management was my business. Health & Safety took up much of our time (and money). As the MD it was me who would have been ultimately criminally liable for any major incidents or accidents. Here, things are done a little differently.

Fortunately Jethro is a skilled carpenter and knew exactly what he was doing. He’s also a heck of a lot more limber than me – and a great deal lighter and smaller. Some tasks were thankfully better suited to his build than mine…

While all this ‘Tool Time’ man’s-work was going on in the yard, outside the compound, over a couple of days, the signwriter had marked out the perimeter wall, chalked in the design and started painting.

Not an easy task. Much of the time was spent dodging the fierce heat and the stair-rod rainstorms that threatened to wash everything away as fast as it hit the wall.

And dodging the kids. Every activity around here draws a crowd – especially when Mzungus are involved.

By the time our last day drew to a close, we’d got the roof onto the drying racks…

…and put up the framework for the work-shelter.

It was disappointing that we couldn’t be there to get the last of the roof sheets and rainwater collection fitted, but we had a plane to catch and Jethro would get it done over the following week.

At least the sign on the outside wall was complete. Over the last 7 days the attention from the local kids has been constant. Most of the time it’s been pretty entertaining, but they’re intrigued by the car and are always crawling all over it, playing with anything they can reach. They may have stolen our petrol cap and radio aerial, peeled some of the stickers off the car and scratched their names into the bodywork, but they seem to like the building signage.